The bow roller was secured by four bolts and two 4” lag screws which came off easily. Under that the chainplate was secured to bronze chock casting and the stem by six 4” # 20 wood screws on top, one 1/2” by 6” machine screw through the top of the stem and five wood screws along the stem. The wood screws required the use of a hammer wrench. Few survived the process.

We tied up in Sturt Bay, Texada Island, British Columbia after bashing through some rough waves near Gibson and noticed that the chainplate for the forestay had separated from the stem of the boat. I had noticed a gap while in Mexico but figured it was just cosmetic. In fact five fasteners had either pulled out or broken. Since we planned on some serious sailing on the West side of Vancouver Island and down to San Francisco this repair couldn’t wait.

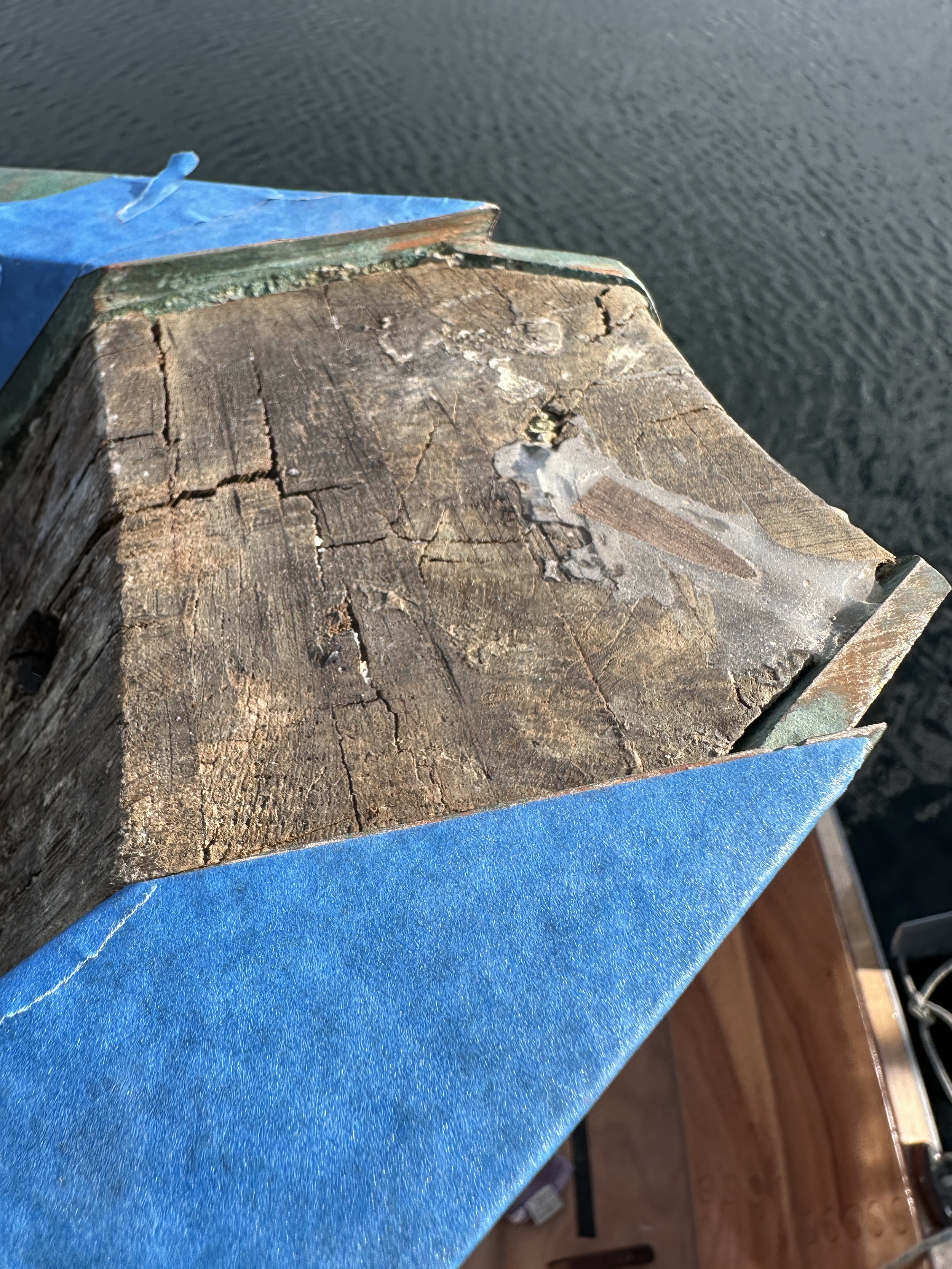

The chainplate casting broke during the extraction process but the good folks at Ocean Pacific Boatyard arranged for it to be welded the same day. It was a huge relief when the wood was exposed and found to be sound. Now all I had to do was drill out the holes to a uniform 1/2” diameter, epoxy in some teak plugs and drill new holes for the replacement fasteners. Complicating matters was lack of a dock so I had to do it all from my trusty but oh so tippy dinghy. Once the holes were drilled and the fasteners dry fitted it was time for a final installation with lots of trusty Sikaflex for the chainplate and Dolfinite for the fasteners.

Gayle and I had a two week layover scheduled in Campbell River for a trip home so with an easy change of plans Gayle left for home and I stayed to repair the chainplate. The first step was to get access to the wood so I removed the forestay, jib furler, pulpit, anchor and chain. All it took was a screwdriver.